Page 1 of 1

Digesting crude biodiesel glycerol

Posted: Sat Feb 16, 2008 4:32 am

by farmer

Hi Gang! I am very very happy to find this forum and get to discuss with you here. I have been scheming to build a digester for over a year... built and drew several prototype schemes in my spare time... this forum is just the medicine for my interest! Thanks to Bob for putting it together.

Anyway like the good folks at Piedmont, we operate a small scale biodiesel plant at a college in Pennsylvania, USA. Our main waste product in biodiesel production is crude glycerol. The glycerol is contaminated with methanol (about 25% by volume) and has a high pH. Our glycerol contains potassium as we use KOH as a catalyst for the BD reaction. Many biodieselers report that it makes good digester feedstock, and I am told that in Europe this is the main disposal route for biodiesel byproduct. In our shop we make about 24 gallons of the liquid byproduct weekly.

I have been working in conjunction with our state's Department of Envrionmental Protection to try to establish what is "Safe, Legal, and Responsible" behaviour for biodiesel production on a small scale. For example, dumping glycerol on the land or in streams is not responsible. Technically, glycerol with methanol contamination is classified as hazardous waste, because it is both ignitible and toxic. The DEP has been reluctant to allow on-farm disposal of crude biodiesel glycerol (CBG) because of this haz-waste classification.

However, if we can show a benefit to using glycerol in a digester (such as increased gas production) and can show that it does no harm (no harmful emissions, and biodegradable effluent) I think the DEP will allow this use. Many small scale biodieselers are interested in biogas digestion, but few of us have ever given it a try.

My hope in posting here, and reading on the forum is to develop a small research project that will demonstrate digestibility of CBG, and come up with a cost effective homescale unit that people can home-brew along with their biodiesel equipment. I was most pleased to see Bob's design on the Biorealis web page and can't wait to get started!

Thanks for your comments.

If you have an interest in biodiesel, the best web sites I know are:

http://biodiesel.infopop.cc (the forum)... drill down into the pages Biodiesel > Glycerine Byproduct to get to the glycerol discussion

http://www.biodieselcommunity.org (the tutorial)

Best regards,

Farmer

Posted: Fri Feb 29, 2008 4:20 pm

by Bob

The glycerol is contaminated with methanol (about 25% by volume)

That seems awful high. Are you recovering (or attempting to recover) any of the methanol?

Thanks for the biodiesel links. Good stuff!

Posted: Fri Feb 29, 2008 5:20 pm

by Bob

Speaking of biodiesel, here is a design I developed a few years ago as one component of a fully sustainable, renewable energy four-season food production facility for a rural Alaska village. The project wasn't fully funded, so this part didn't get built. What's unique about it is that it uses waste heat from the engine coolant system as process heat.

The idea was to grow plants aquaponically (a symbiotic combination of aquaculture and hydroponics, where the plant roots harbor nitrifying bacteria that purify the fish water, while the fish provide nutrient for the plants) under lights in an insulated building. The lights were powered by a diesel generator running on a combination of biodiesel and syngas generated from the thousands of acres of beetle-killed spruce forest owned by the tribe. The generator provided all heat required for the facility as well as process heat for gasification and biodiesel production.

There is a 'mind-map' presentation of the whole scheme

here. (Hint: Click on nodes to expand or collapse them

For a larger copy of the image (pdf file)

click here.

Posted: Sat Mar 01, 2008 1:25 pm

by farmer

Nice biodiesel design Bob! Looks like you've seen a few of these in action. We are doing something similar in our shop, with the following modifications:

1.Solar hot water system for oil preheat (instead of engine process heat)

2.We've added a settling tank between the reactor and the wash tank. The water heaters don't drain all that cleanly, so you always get a little glycerol in the tank after the reactor. We let this drop out for a day or so before pumping to the wash.

3. We used an 80 gal water heater for 54 gallon batches... same amount of labor for more fuel.

4. We are doing methanol recovery from fuel and glycerol at ambient pressure... there is some debate on the biodiesel forum as to whether vaccuum really brings you any efficiency gains during methanol recovery. Ambient works OK for us. My methanol recovery mentor at infopop is Graham Laming, if you're interested I recommend a look at his series of articles including top notch reactor and heat exchanger designs at

http://www.graham-laming.com

5. We have a glycerol storage drum that we can pump to and from the reactor... when we have 50-60 gal on hand we pump it back in for methanol recovery.

6. Everything is vented to the outside via a simple system of tubing.

Anyway I could go on and on, but try not to!

Best wishes,

farmer

Methanol recovery

Posted: Sat Mar 01, 2008 1:27 pm

by farmer

Oh yeah, we recover methanol from our glycerol but not everybody does. We are trying to work out some viable options for use of the glycerol if people don't want to do methanol recovery... right now trying to get the PA DEP to allow glycerol with methanol (technically hazardous waste) to be fed to a digester in PA.

Turns out methanol recovery is a lot easier than starting a whole new project (like a digester) but somebody might have a neighborhood digester to feed...

Thanks,

Farmer

Posted: Sat Mar 01, 2008 7:22 pm

by Bob

Wow! I just spent some time at Graham Laming's website. What a great bunch of information.

There is far more -- and better -- information available now than there was when I last was into this a few years ago.

Thanks for the pointer, farmer.

Posted: Sun Mar 02, 2008 5:37 pm

by farmer

You bet Bob. If you want to attract a few more biodiesel nuts to this forum, just say the word and I'll post a message on the "alt uses for glycerol byproduct" thread.

Cheers,

farmer

Re: Digesting crude biodiesel glycerol

Posted: Sat Apr 25, 2009 6:44 am

by tgbatzler

Found this site and just joined.

It's been a year on this thread and just wondering if there's anything new associated with experiments on digestibility of biodiesel glycerol?

Friend of mine and I have built our own system and I recover the methanol from the glycerin by-product. Currently composting the

glycerin and, based on how 'happy' my compost bugs are, am thinking there's got to be a better use for converting this to energy that I can use...

Saw a picture of a pilot digester for experimenting with digesting glycerin? What were the results of your testing??

Re: Digesting crude biodiesel glycerol

Posted: Sat Apr 25, 2009 12:41 pm

by Bob

...am thinking there's got to be a better use for converting this to energy that I can use...

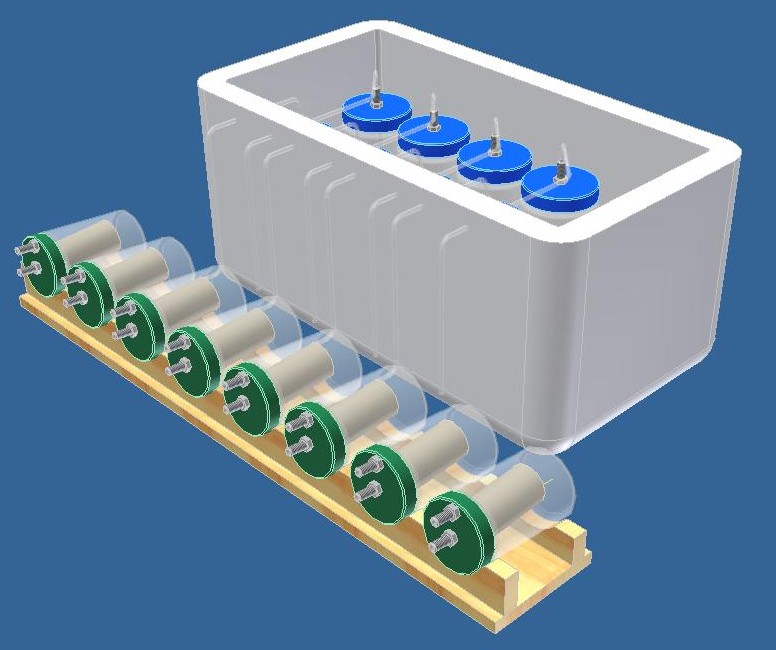

I agree -- which is the motivation for developing a couple of products, including the lab-scale digester shown in the attached pic, and a how-to construction manual to go with it. (A work in progress...)

What were the results of your testing??

Indeterminate. Testing is still in progress. In theory, though, glycerol, a sugar alcohol, should be far easier to digest than, say, cow manure or WWTP sludge.

Saw a picture of a pilot digester for experimenting with digesting glycerin?

(Where did you see it? On the

Dickinson College Sustainability Site?)

- digester-horizontal2.jpg (76.29KiB)Viewed 58408 times

Re: Digesting crude biodiesel glycerol

Posted: Sun Apr 26, 2009 5:23 am

by tgbatzler

I saw it on this site... someplace. Now that I'd like to point you to the thread, I can't find it.....When I stumble across it, I'll let you know. Very similar to the picture you posted...6 digesters, pressure switch, pond pump, cooler...probably v1.0...

Visited the Dickinson College link and read through the pilot digester progress. Are you open to accepting help from someone with 20+ years in product development with particular focus on power electronics, motor control/drives, embedded hardware and software development in the welding power source industry?? Not looking for job, just information 'exchange'...

Friend of mine and I designed a customized control scheme for his bio-diesel system. He did the plumbing, I created the schematic, did the board layout and software for the custom 'PLC' to control all the heating, valves and pump assemblies..Then I did the same to semi-automate (work-in-progress) the methanol recovery piece. With that in-hand I've turned our attention to glycerin and wash-water 'mitigation' in a responsible and sustainable manner.

Re: Digesting crude biodiesel glycerol

Posted: Mon Apr 27, 2009 4:46 am

by mathewjenkinson

Hi Bob, long time no chat.

hi Farmer, i too am a biodiesel nut, ive spent the last few years working with biodiesel as my final year project and am now looking to develop further into biogas.

Im at the final steps of my design now and have a quick question: Even tho methanol is toxic to organic life is it safe to put raw glryc from my biodiesel reactor (about 20l a week) straight into the anaerobic digester or is it better to remove the methanol 1st and then add to the digester?

Have you started construction on your AD reactor yet?

Re: Digesting crude biodiesel glycerol

Posted: Mon Apr 27, 2009 6:31 pm

by Bob

re my "where did you see it question:

I saw it on this site... someplace. Now that I'd like to point you to the thread, I can't find it

Hah. I found it -- thanks to Mathew's intervening post. Searching for his earlier posts I stumbled across it

in this thread.

Even tho methanol is toxic to organic life is it safe to put raw glryc from my biodiesel reactor (about 20l a week) straight into the anaerobic digester or is it better to remove the methanol 1st and then add to the digester?

Actually, methanol is not toxic to all organic life -- in fact,

this wikipedia article says it is readily biodegradable in both aerobic and anaerobic environments. I suspect that it comes down to the

rate at which it is added to the digester, relative to the size of the bacterial population. Too much added too fast will kill it, but not slow-feeding -- i.e. limited by the rate at which the bugs can metabolize it. (Sounds like a great question to answer by testing with the lab-scale digester.)

Re: Digesting crude biodiesel glycerol

Posted: Tue Apr 28, 2009 9:49 am

by mathewjenkinson

hummmm.

Well im about to build a test rig, with a 20l container - so it would be a batch container.

I have access to raw glryc, cow waste, grass cuttings and human waste.

I was going to put 5 litres of raw glyrc in the mix and see where it went from there? or do you suggest more or less?

Re: Digesting crude biodiesel glycerol

Posted: Tue Apr 28, 2009 12:31 pm

by Bob

Good question. Probably the most important thing is to be sure that you have a good live population of methanogens. And enough buffering capacity to keep the pH from dropping if you overload it.

Re: Digesting crude biodiesel glycerol

Posted: Mon May 11, 2009 5:06 pm

by tgbatzler

Mathew,

I'd think you'd want to recover the methanol just from the economic perspective. Based on the price per gallon I can justify the recovery, if I don't factor in my time, that is. Most of the time investment is dealing with the glycerin after methanol recovery. Which, in a nutshell, is why I'm lurking in the wings learning what I can to create an 'in-line' digester.